Aluminium sheets are a popular material choice for outdoor furniture in Australia. They’re lightweight, corrosion-resistant, and easy to work with. But like any material, aluminium sheets aren’t completely problem-free. Understanding the issues that can arise, how to prevent them, and why aluminium is still a strong contender in outdoor furniture projects will help you get the most out of your investment.

1. Surface Scratching and Dents

One of the main issues with aluminium sheets, especially in outdoor environments, is how easily the surface can get scratched or dented. Aluminium is a soft metal compared to steel, so even minor impacts from outdoor use—like moving chairs, falling branches, or scraping against hard surfaces—can leave marks.

How to Prevent It

Choosing thicker gauge aluminium sheets helps. Thicker sheets are less prone to warping and denting. Applying protective powder coatings or anodising the surface also adds a more scratch-resistant layer. These coatings won’t make aluminium invincible, but they offer a solid buffer against everyday wear and tear.

2. Heat Retention and Surface Temperature

Australia’s hot summers can turn metal furniture into heat traps. Aluminium, being a metal, absorbs and holds heat, which means outdoor aluminium furniture can get uncomfortably hot to touch or sit on during sunny days.

How to Prevent It

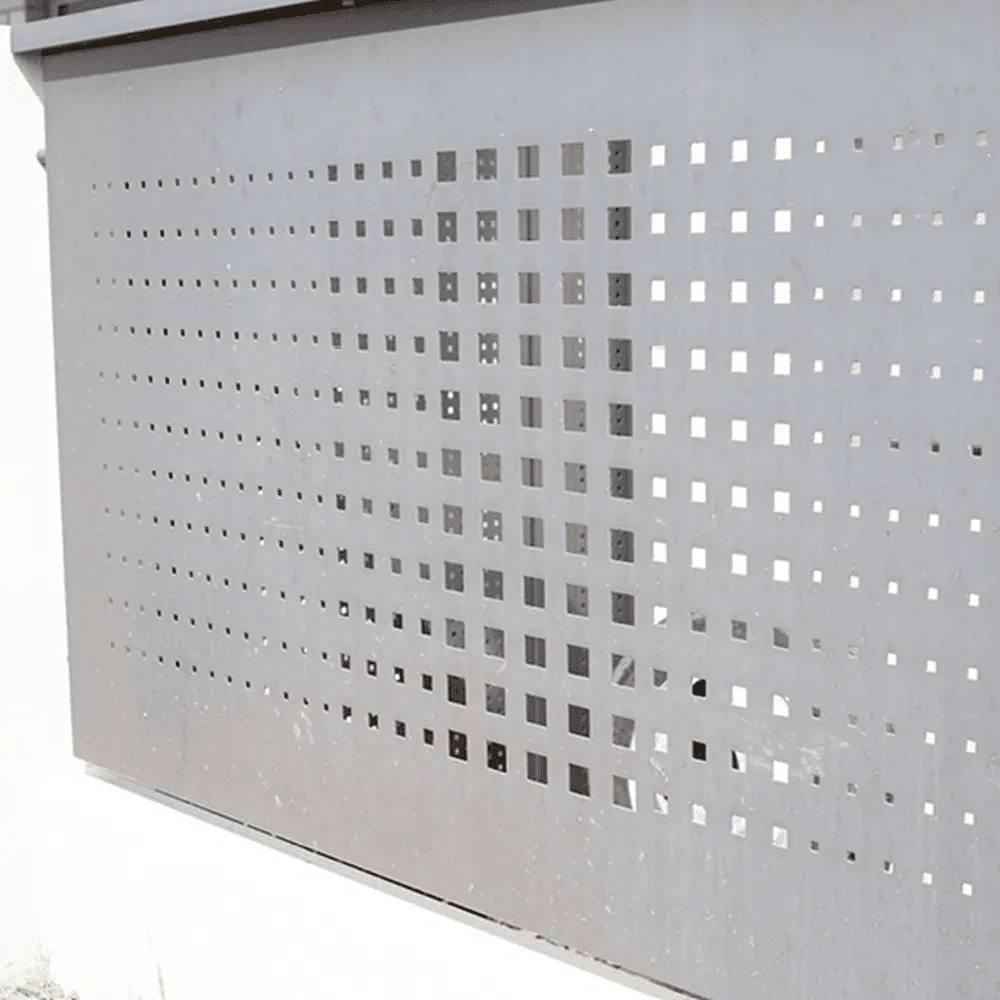

Designing with heat in mind is key. Slotted or perforated aluminium sheet designs reduce surface area, helping air circulate and heat dissipate faster. Light-coloured finishes or heat-reflective coatings also minimise surface temperature buildup.

Using cushions, timber slats, or fabric covers in contact areas is another practical fix. These not only improve comfort but also protect from direct skin-to-metal contact.

3. Galvanic Corrosion When Mixed With Other Metals

Aluminium doesn’t rust, but it can corrode when in contact with dissimilar metals like steel or copper in the presence of moisture. This is called galvanic corrosion, and it’s a concern in mixed-material furniture, particularly at screws, bolts, or frames.

How to Prevent It

Avoid metal-on-metal contact where possible. Use plastic or rubber washers as separators between aluminium and other metals. Stainless steel fasteners are usually safe to use, but it’s still best to isolate them from direct contact when used with aluminium.

Sealing joints and coating the aluminium surface (powder coating or anodising) reduces exposure to moisture, further lowering the risk.

4. Bending and Warping Over Time

Because aluminium is lightweight and relatively flexible, furniture made with thin or unsupported sheet sections can eventually warp, especially under constant pressure or in high-traffic settings. Outdoor heat can also contribute to expansion and warping.

How to Prevent It

Choosing the right thickness and structural support makes a big difference. Aluminium sheets should be backed with a solid frame—preferably aluminium tubing or reinforced ribs—to prevent flexing. Avoid large flat spans with no support underneath.

Proper installation techniques and choosing heat-treated or hardened aluminium alloys for structural parts can also improve rigidity.

5. Discolouration and Oxidation

While aluminium doesn’t rust, it can oxidise and discolour when exposed to the elements. The result is often a dull, chalky layer or patchy surface that takes away from the sleek finish many people look for in modern outdoor furniture.

How to Prevent It

Anodising or powder coating the aluminium surface helps prevent oxidation. Regular cleaning with mild soap and water also keeps contaminants (like salty air or bird droppings) from accelerating discolouration.

Avoid harsh chemical cleaners or abrasive pads—these can damage protective coatings and speed up surface wear.

6. Limited Weight-Bearing Capacity

If aluminium sheets are used without reinforcement or as load-bearing surfaces, they can flex or buckle under heavy weight. This becomes a problem in things like bench seats, tables, or lounges where people expect reliable support.

How to Prevent It

Aluminium sheets shouldn’t be used as structural elements without additional support. Pairing the sheets with a tubular aluminium frame or substructure increases load-bearing capacity.

Using thicker gauge sheets for parts expected to carry weight—like seat panels—is a straightforward way to boost strength without switching to a heavier material.

7. Cost of High-Quality Finishing

Aluminium sheets are cost-effective on their own, but adding coatings, custom cutting, welding, or bending can increase costs—especially when trying to achieve high-end designs or finishes.

How to Prevent It

The key is smart design and planning. Keeping designs simple and using standard sheet sizes can reduce cutting waste. Powder coating in bulk or using pre-finished sheets can also bring the per-unit cost down.

For outdoor furniture projects, it’s worth investing upfront in higher-quality finishes to reduce maintenance and extend the product’s lifespan.

Aluminium Sheets: Still One of the Best Options for Outdoor Furniture

Despite these potential issues, aluminium sheets continue to be a solid, practical choice for outdoor furniture. They’re lightweight, resistant to corrosion, and can be shaped into almost any form—making them ideal for both classic and creative designs.